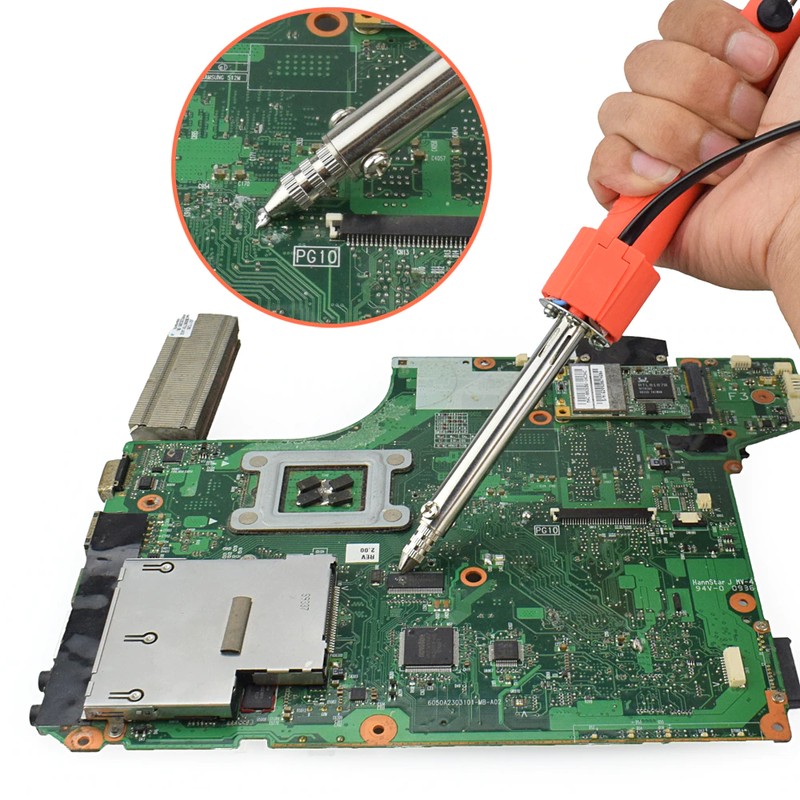

Electric Solder Sucker Welding Pump/Soldering Iron/Removal Solder Iron Pen Welding Tool

- 140 reviews

- 736 Sold

Customer Reviews

*Note: Some reviews have been processed by Google Translate!Certification: CE

Model Number: HB-019

is_customized: Yes

Material: High temperature resistant material

Maximum suction: 5 (cm-Hg)

Power: 36W

Working Voltage: 220V

Scope of application: Tin melting + Tin absorption

Plug Type: EU/US plug

NEWACALOX 220V 50Hz EU Electric Vacuum Solder Sucker Welding Desoldering Pump/Soldering Iron/Repair Tool/Removal Solder Iron Pen+Drill rod

Description:

Material: High temperature resistant material

Maximum suction: 5 (cm-Hg)

Power: 36W

Working Voltage: 220V/110V

Plug Type: EU plug/US plug

Scope of application: Tin melting +Tin absorption

Feature:

1.Compact size

2.Pure copper power cord

3.Sensitive trigger switch

4.Seamless stainless steel pipe

5.All metal suction nozzle

6.High temperature nylon handle

7.Tin melting + tin absorption, one-handed operation

8.Electric dual-use suction device has a beautiful appearance, novel structure, easy to use and other features

9.It can easily suck all the solder joints and remove the components to be replaced from the circuit board without damaging components and circuit boards.

10.Very convenient to replace integrated circuits, multi-foot switches

11.One-handed heating and tin absorption can be completed at the same time in two steps, you can accurately absorb the melting solder, smooth removal of parts.

12.Can be used as a general soldering iron, is an essential tool for national defense, scientific research, communication, aerospace, computer, radio, television, electronic professional maintenance personnel and the majority of radio enthusiasts.

Package Includes:

1 xElectricDual-use Desoldering Pump

1 x Drill rod

Instructions:

1,Suction tin working voltage 220V-50Hz, power 36W

2, turn on the power, warm up 3-5 minutes

3,Push the piston handle down and hold the tip of the suction nozzle at the target solder joint. After the solder melts, press the control button and the solder is sucked into the air cylinder.

4, the suction device is equipped with two different diameter suction nozzles, which can be selected according to the thickness of the component leads.

5, when welding, the operation method is consistent with the electric iron

6. When disassembling the gas cylinder, press the upper end of the gas cylinder down in the direction of the arrow. At the same time, pull the gas cylinder and handle away, and the gas cylinder can be separated. When removing the suction nozzle, rotate the suction nozzle counterclockwise to remove the suction nozzle

Precautions

1, check the voltage, high or low voltage is not conducive to use

2, before use, the suction nozzle and the gas cylinder should be tightened to prevent leakage, otherwise the effect of tin absorption will be affected.

3, often remove the solder impurities into the suction nozzle and gas cylinder, and add a little oil to the piston

4, after each use, it is necessary to push the piston 3-4 times to remove the residual solder in the suction tube, so that the suction nozzle and the suction tube can be kept open for the next use

5, it is forbidden to install or disassemble the sucker when it is powered on

6,When the suction device is used for the first time, it may be slightly smoked due to heating of the heating element. This is a normal phenomenon and will naturally disappear after 10 minutes.

7,In the course of use, the iron base with natural heat dissipation structure must be used, and it should be placed in the iron seat

8,If the power cord is damaged, it must be replaced by the manufacturer or its maintenance department or a similar professional to avoid danger.

9, this product has a ground wire, should be equipped with a socket with contacts, please be careful to use for safety.

Note:

1.Please allow 1-3mm error due to manual measurement, please make sure you can accept it before paying for it.

2.Due to the difference between different monitors, the picture may not reflect the actual color of the item.