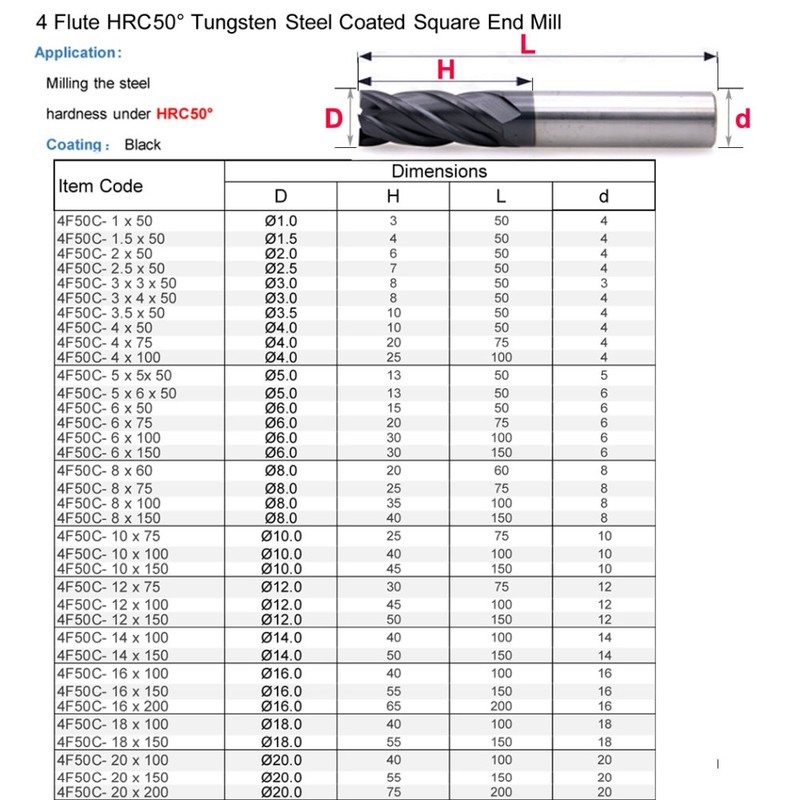

Discount Price Cutting Hrc50 4 Flute 4Mm 5Mm 6Mm 8Mm 12Mm Alloy Carbide Milling Steel Milling Cutter End Mill

- 140 reviews

- 1894 Sold

Customer Reviews

*Note: Some reviews have been processed by Google Translate!Certification: NONE

Type: End Mill

Overall Length: 50mm 75mm 100mm

Model Number: 4F50C

Diameter: 2mm 4mm 8mm 10mm 12mm

Coating: TiAIN

Material: Carbide

MZG Discount Price Cutting HRC50 4 Flute 4mm 5mm 6mm 8mm 12mm Alloy Carbide Milling Tungsten Steel Milling Cutter End Mill

1.MZG End Mill Item Specifics

MZG End MillsSpecification Parameter

2.MZG End MillProduct Photo

3.MZG End Mill Packing Info

End Mill Packing Info

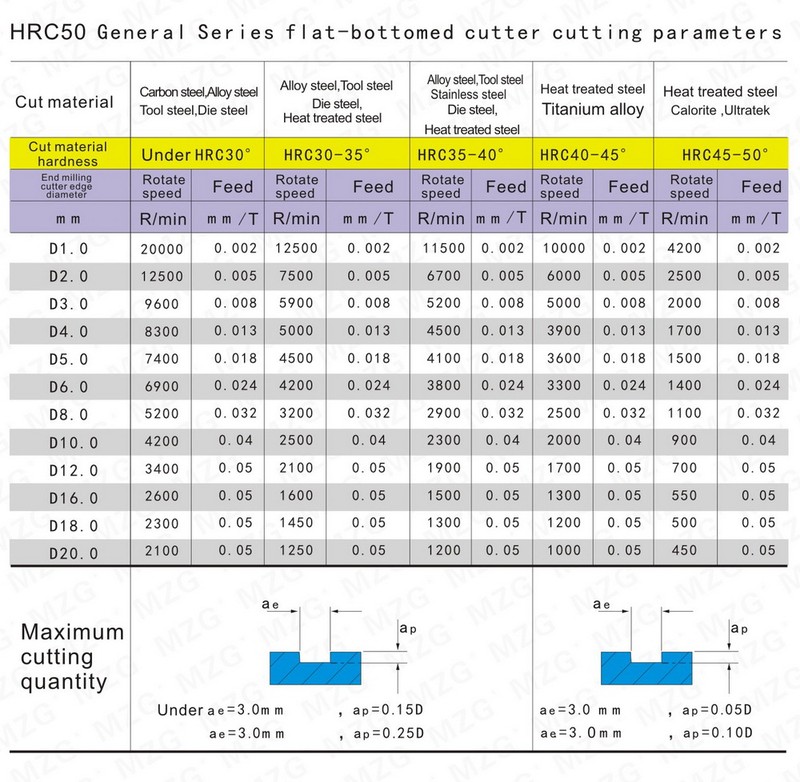

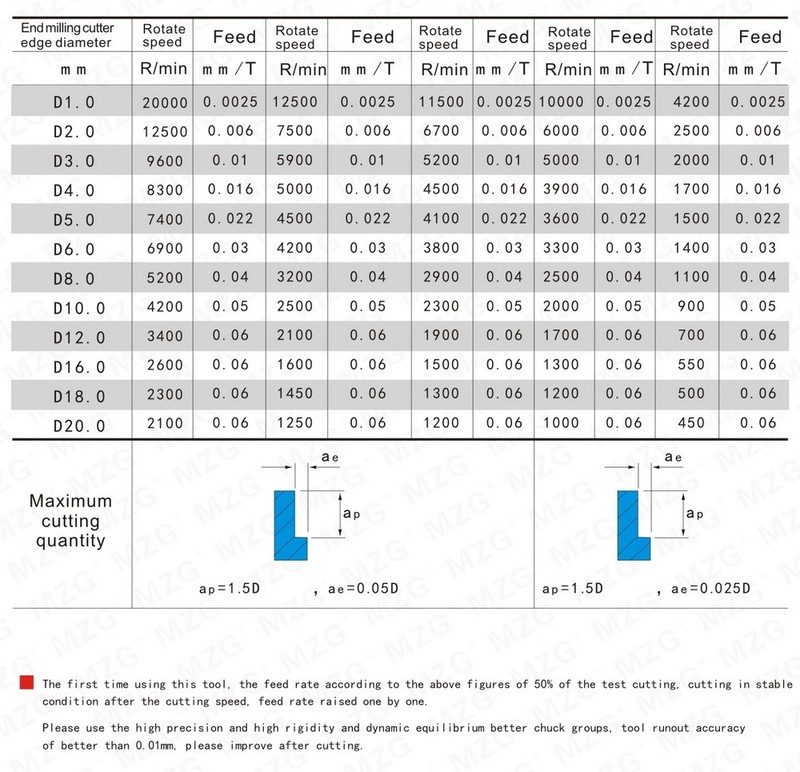

4.MZG End Mill Parameter

5.MZG End MillInstruction

Safety Notes for Cutting Tool

1 Introduction

2 Basis Information for Cutting Tool Materials

2-1 Technical Terms

2-2 Physical Properties

2-3 Composition

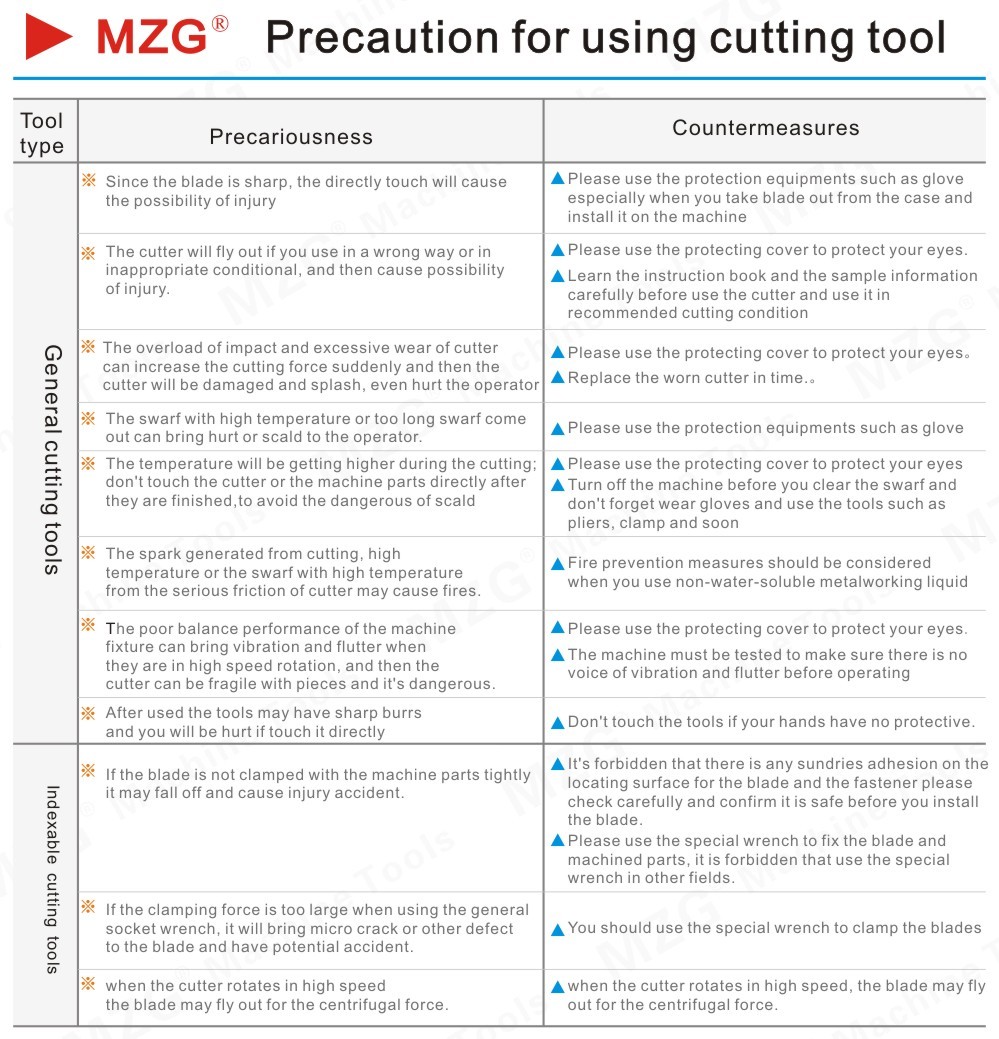

Precaution for using cutting tool

1.General Cutting Tools

Precaution for using cutting tools

Precariousness: Direct touch to a sharp cutting edge may cause injury.

Countermeasures: When you set up tools to the machine or take tools out of the case, please wear protective gloves.

Precariousness: Misuse or inappropriate working conditions may cause tool breakage or dispersion of broken pieces.

Countermeasures:Please use safety item, such as safety glasses and protective gloves

Please use in the range of our recommended cutting condition. See our catalog or instruction manuals.

Precariousness: Excessive impact or heavy wear will increase cutting resistance and may cause tool breakage and dispersion of broken pieces.

Countermeasures: Please use safety item, such as safety glasses and protective gloves

Early exchanging tools is preferable.

Precariousness: Dispersion of heated or prolonged chips may cause injury or burn.

Countermeasures: Please use safety item, such as safety glasses and protective gloves

For chips removal, please stop the machine beforehand and use safety items, such as safety glasses and protectives gloves.

Precariousness: Tools and materials reach high temperatures during cutting operation. Direct touch to the tools and materials shortly after cutting may cause burn.

Countermeasures:Please use safety item, such as safety glasses and protective gloves

Precariousness: Sparks, generation of heat or chips in high temperature during operation may cause file.

Countermeasures: Please do not operate around Hazardous zone, in which there is some possibility of fire or explosion.

In case of using oil-coolant, please make sure there is sufficient fire-protection equipment.

Precariousness: Lack of dynamic balance during high-speed revolutions leads to vibrations which can make the tool break.

Countermeasures: Please use safety item, such as safety glasses and protective gloves

Please conduct test-operation before cutting, and confirm that there is no vibration or unusual sound.

Precariousness: Direct touch to the burs which were generated on the rough surface of the workpiece may cause injury.

Countermeasures: Do not touch the workpiece with bare hand.

2.IndexableCutting Tools

Precariousness: If the insert or other tool parts are not installed properly, they can fall down or break which may cause injuries.

Countermeasures: Please clean up insert pockets or clamping parts before setting insert.

Please set up inserts with supplied wrench only, and confirm that the inserts or parts are clamped completely. Never use inserts or parts other than those prescribed.

Precariousness: If inserts are clamped too tightly by supplementary tools like pipe etc. inserts or body may break.

Countermeasures: Do not use aids such as pipes. Please set up using supplied wrench only.

Precariousness: When tools are used in high-speed revolution, inserts or parts may burst out of the body due to centrifugal force. When handling, please pay special handling to safety.

Countermeasures: Please use in the range of our recommended cutting condition. Accuracy and balance of machine spindle should be checked and adjusted regularly to prevent wear of the bearing due to eccentric rotation.

3.Milling Cutters and other Cutting Tools

Precariousness: Since milling cutter have sharp edged, direct contact with bare hands may cause injury

Countermeasures: Please use safety item, such as safety glasses and protective gloves

Precariousness: If a cutter lack balance, the tool can start to vibrate. The dispersion of broken piece can cause injuries.

Countermeasures: Please use in the range of our recommended cutting condition.

Accuracy and balance of machine spindle should be checked and adjusted regularly to prevent wear of the bearing due to eccentric rotation.

4.Drilling

Precariousness: When drilling a through-bore, it is possible that a disc is created during the drilling procedure that can fly out of the workpiece at a high speed.

This is very dangerous since the disc has sharp edges.

Countermeasures: Please use safety items, such as safety glasses and protective gloves. Also attach a cover on a chuck part.

5.Brazed Tools

Precariousness: Dispersion of falling down of broken inserts may cause injury.

Countermeasures:Please Check that the cutting inserts are brazed firmly before use.

Please do not use brazed tools in the condition that requires high cutting temperature.

6.Others

Precariousness: If Brazing is carried out many times, the strength of carbide insert is deteriorated and can break easily during cutting

Countermeasures: Please do not use tools that have brazed several times. The quality of the tool deteriorates.

Precariousness: The tools can only be used for the appropriate application. It may damage tools and machines.

Countermeasures: Please follow our recommended usage for the tools.

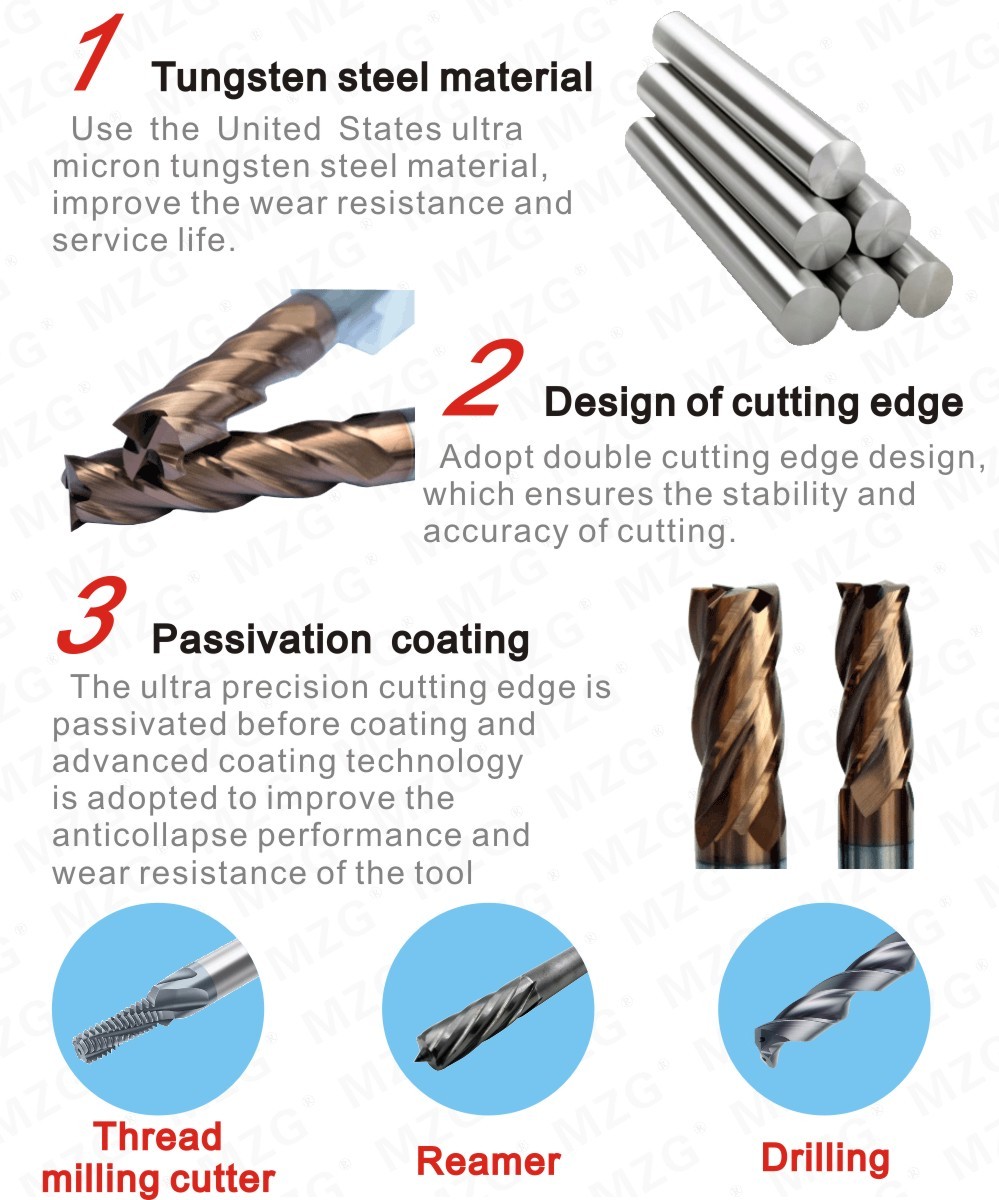

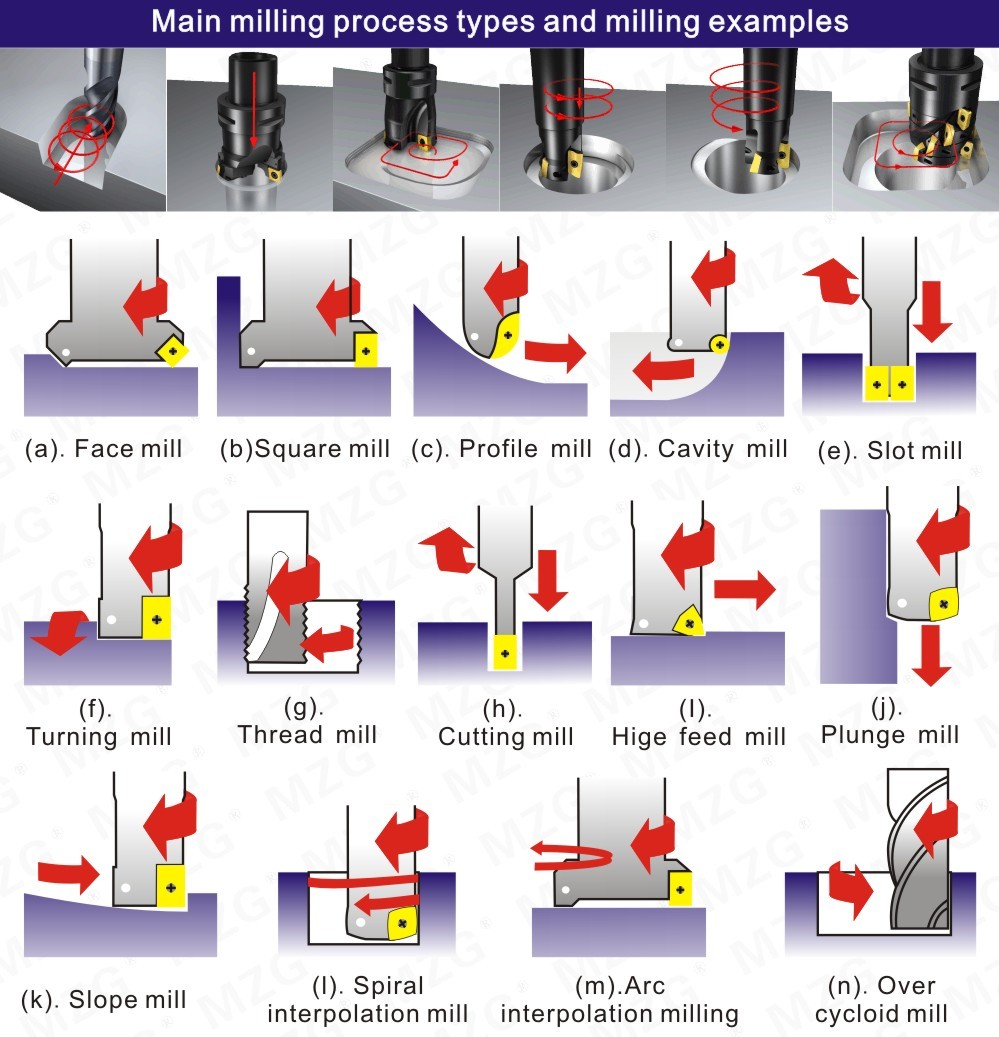

6.MZG End Mill Application

Application Machine:

Milling machine

Milling Center

Large-scale Milling machine

Processing mode and Finished product samples

Shoulder Milling

Thread Milling

Inner Hole Boring

Fine Hole Boring

External Boring

Face Milling

T Groove End Milling