220V Arc Semi-Automatic Welding Machine Automatic Digital Current Thrust Fit 2.5Mm Electrodes 4600W

- 137 reviews

- 419 Sold

Customer Reviews

*Note: Some reviews have been processed by Google Translate!Certification: NONE

Dimensions: 250*100*250mm

Arc Current: 120A

Usage: Welding

Is Smart Device: NO

Plug Type: EU plug

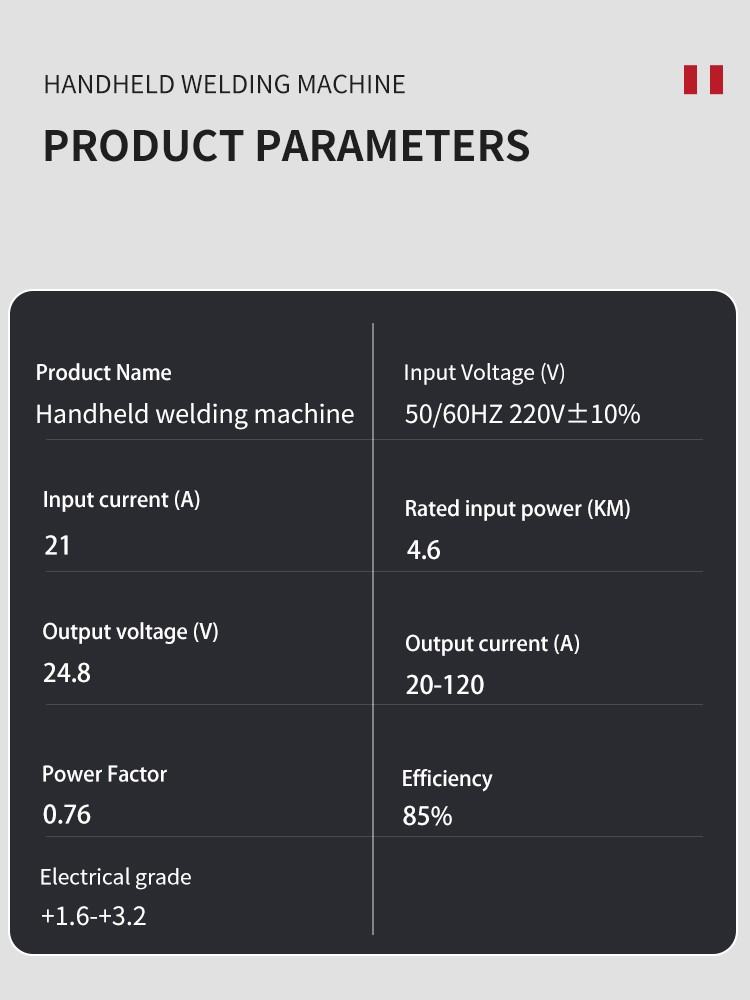

Input voltage(V)50/60Hz: 220V±10%

Input Current(A): 21

Rated output voltage(V): 24.8

Output Current(A): 20-120

Rated Input Power(KW): 4.6

protection class of case: IP21

Dimension(mm): 250x100x250

N.W(K.G): 1.8

Power factor: 0.76

Efficiency: 85%

Input Voltage(V) 50/60Hz :220V±10%

Input Current(A) :21

Rated output voltage(V) :24.8

Output Current(A) :20-120

Rated Input Power(KW) :4.6

protection class of case :IP21

Electrode: φ1.6-φ3.2

Dimension(mm) :250x100x250

N.W(K.G): 1.8

Power factor :0.76

Insulation class: F

Duty Cycle at 40℃ :20%

Efficiency :85%

detailed list:

All product accessories are included in the picture

1. ARC Welding machine

2. 1. 6 M2 crocodile clip 1.5m;

3. 1.5 square meters of power line;

4. Steel brush;

5. Instructions

Questions and answers

Q1.Does it use conventional electrodes or need special electrodes?

A1.It use 2.5mm electrodes.

Q2.Is it a battery device or does it come from a 220 V voltage?

A2.It uses voltage from 220 V.

Q3. What is its weight and is it easy to operate with one hand?

A3.Small in size and it works well with one hand. You can also buy a stand for the right device and put the device on the stand when you work.

Q4.What scenarios are the machines suitable for working in?

A4.Suitable for home office, travel and so on any scene, it comes with a lightweight toolbox, easy to carry around.

Q5.The arrival logistics time limit of the goods?

A5.Five-day delivery to Korea.Brazil and the United States are around 20 days, France and Germany are around 15 days, Spain is around 10 days and Russia is about 7 days.

5.1 Working Environment

Welding should be carried out in a relatively dry environment with its humidity of 90% or less.

The temperature of the working environment should be within -10°C to 40°C.

Avoid welding in the open air unless sheltered from sunlight and rain, and never let rain or water infilter the machine.

Avoid welding in dusty area or environment with corrosive chemical gas.

Avoid gas shielded arc welding in environment with strong airflow.

5.2 Good Ventilation

This welding machine has so big welding current when working that nature ventilation can not meet the cooling demand, while the inner fan enables the machine to work steadily by its effective cooling. Operator should make sure the louvers are uncovered and unblocked. The minimum distance between the machine and nearby objects should be 30cm. Good ventilation is of critical importance to the normal performance and service life of the machine.

5.3 No Overvoltage

If the voltage exceeds the permitted limit, the machine will be damaged, so pay attention to the changes in voltage. Once overvoltage occurs, stop welding and switch off the power.

5.4No Overload

Remember to observe the max load current at any moment (refer to the optioned duty cycle). Make sure that the welding current should not exceed the max load current. Over-load current could obviously shorten the welding equipment's life, or even burn the equipment.

5.5Overheating Protection

Overheating protection appears while the machine is of overload status because of continuous welding for a long time, and a sudden halt of welding occurs. In this case, it is unnecessary to restart the machine, but just wait for the overheating LED to go out, and welding can be recovered.

6. MAINTENANCE

1. Check periodically whether inner circuit connection is ok (esp. plugs). Tighten the loose connection. If there is oxidization, remove it with sandpaper and then reconnect.

2. Keep hands, hair and tools away from the moving parts such as the fan to avoid personal injury or machine damage.

3. Clean the dust periodically with dry and clean compressed air. If welding in environment with heavy smoke and pollution, the machine should be cleaned daily. The pressure of compressed air should be at a proper lever lest the small parts inside the machine be damaged.

4. Avoid rain, water and vapor infilter the machine. If there is, dry it and check the insulation with a megger (including that between the connections and that between the connection and the case). Only when there is no abnormal phenomena can welding be continued.

5. Check periodically whether the insulation skin of all cables are perfect. If there is any dilapidation, wrap it or replace it.

6. Check periodically whether thegas hosehasany cracks. If any, get them replaced.

7. Put the machine into the original packing in dry location if it is not to be used for a long time.