사용자 리뷰

*참고: 일부 리뷰는 Google 번역에서 처리되었습니다!인증 : CE

작동 전류 : 알 수없는

용접 전류 : 알 수없는

작동 온도 : 500 c

모델 번호 : 용접로드

응용 프로그램 : muti

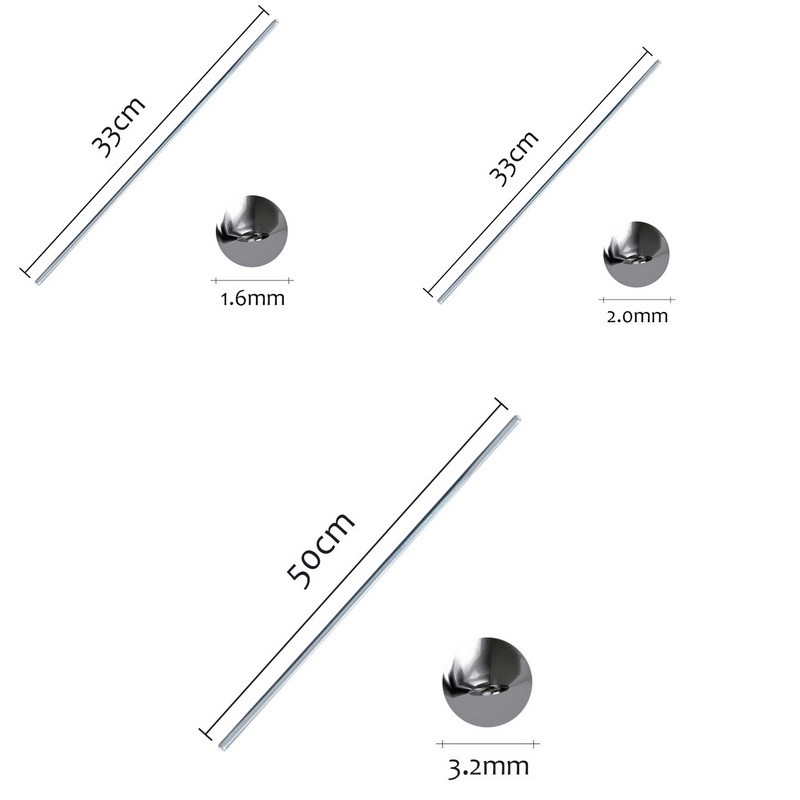

길이 : 50cm

항목 설명

사양

제품 사양

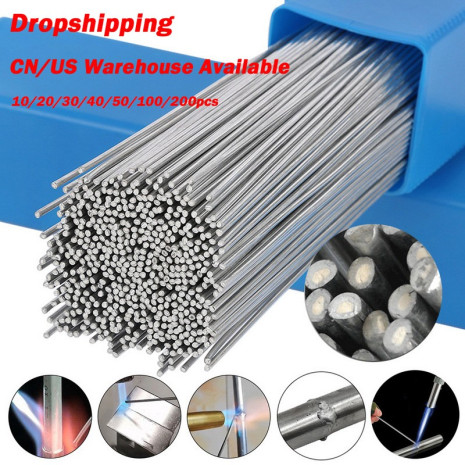

수량: 20/10/30/50pcs

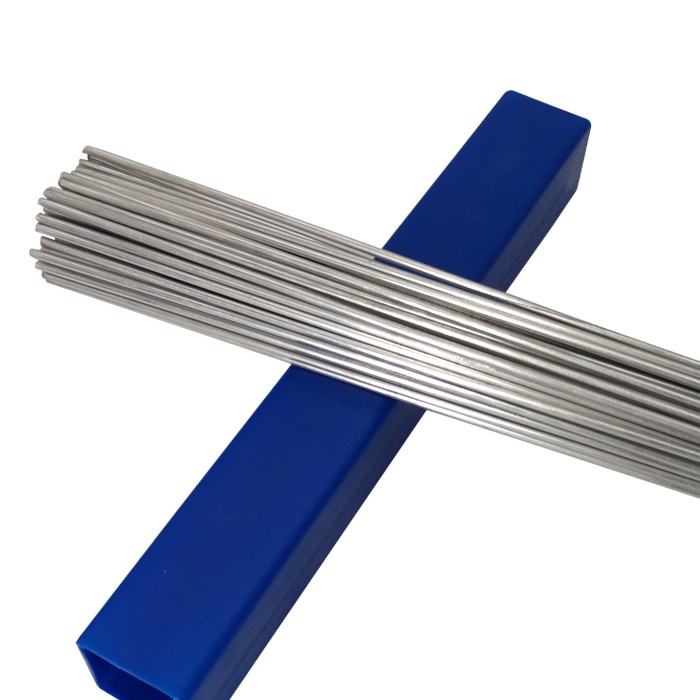

물자: 알루미늄

색상: 실버

작동 온도: 420 °

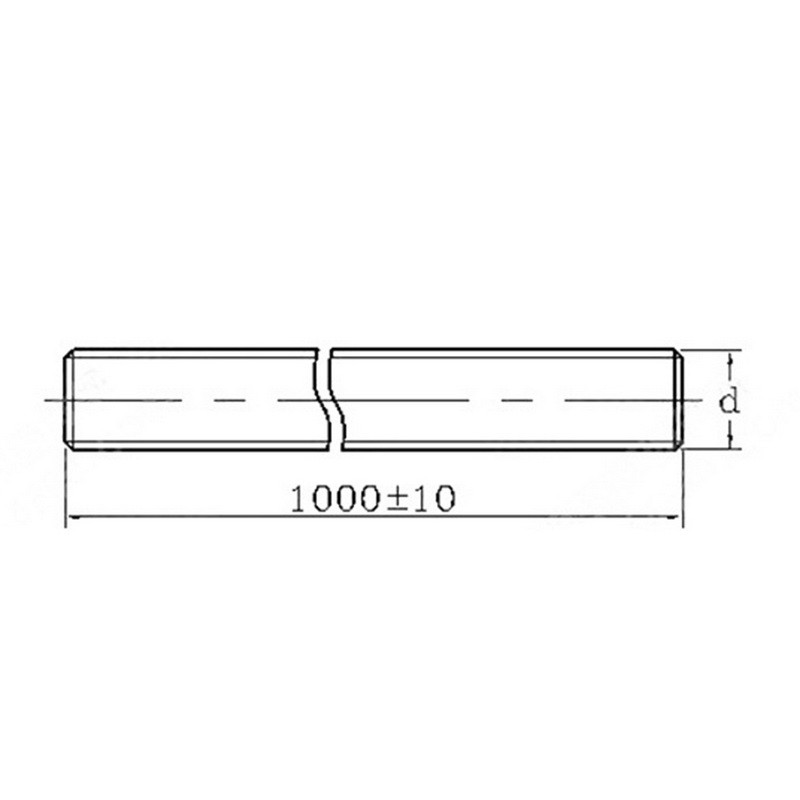

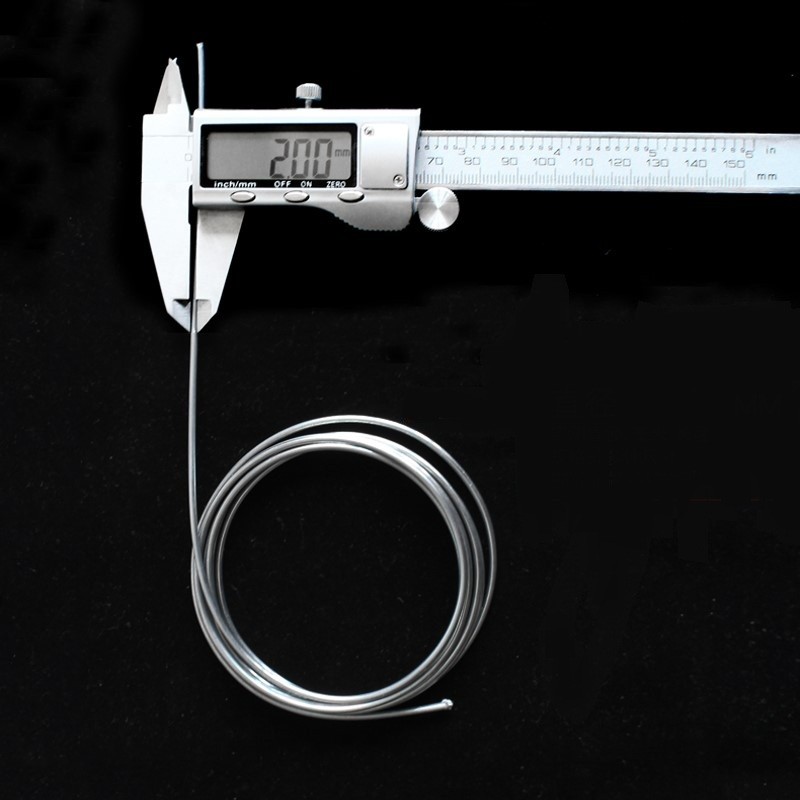

직경: 2mm / 0.08 ", 1.6mm/ 0.06"

길이: 500mm/19.7"

제품 사양

수량: 20/10/30/50pcs

물자: 알루미늄

색상: 실버

작동 온도: 420 °

직경: 2mm / 0.08 ", 1.6mm/ 0.06"

길이: 500mm/19.7"

패키지 목록:

20 * 알루미늄 용접 와이어

10 * 알루미늄 용접 와이어

30 * 알루미늄 용접 철사

50 * 알루미늄 용접 와이어

20 * 알루미늄 용접 와이어

10 * 알루미늄 용접 와이어

30 * 알루미늄 용접 철사

50 * 알루미늄 용접 와이어

특징:

1. 널리 사용-용접 또는 표면 용접 합금 고강도, 좋은 forgeability & 좋은 내식성.

2. 좋은 품질 물자 -- 알루미늄 물자, nontoxic, 무취 및 튼튼한 물자로 만드는.

3. 필요로 한 땜납 분말 없음 -- 용접 핵심으로 알루미늄 합금으로 다른 유출 분말을 사용하고 소금 기초로 코팅하는 아무 필요도 없습니다.

4. 신청 -- 철사를 금속을 입히는 용접 충전물 철사와 살포 및 화염을 포함합니다. 그것은 또한 순수한 알루미늄을 위한 아르곤 아크 용접 그리고 채우는 물자를 위해 사용해, 전해질 알루미늄 식물의 알루미늄 버스 그리고 가이드 막대와 연결 및 전력, 화학, 음식 등.

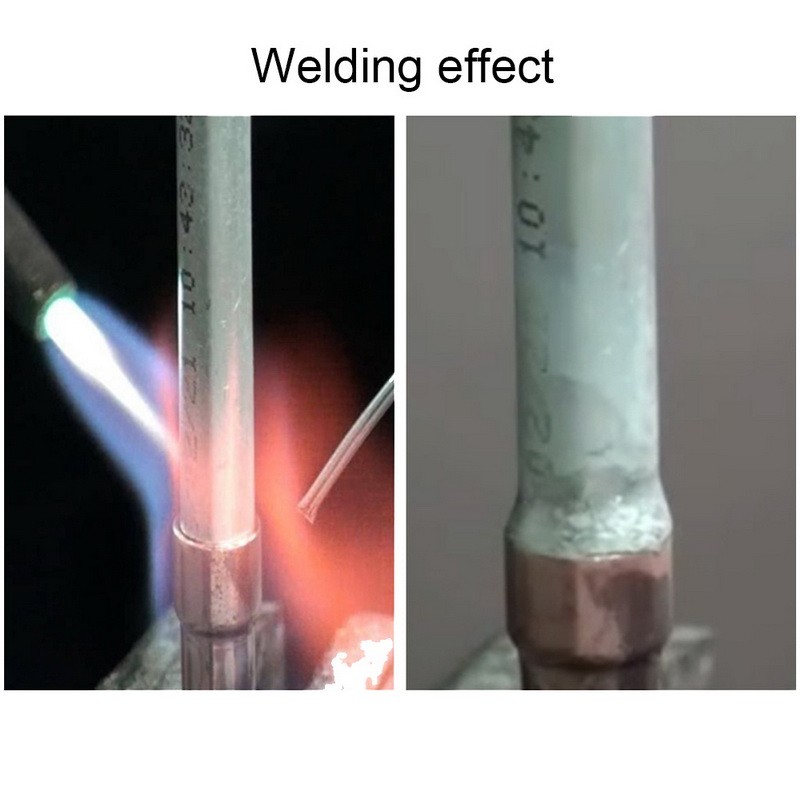

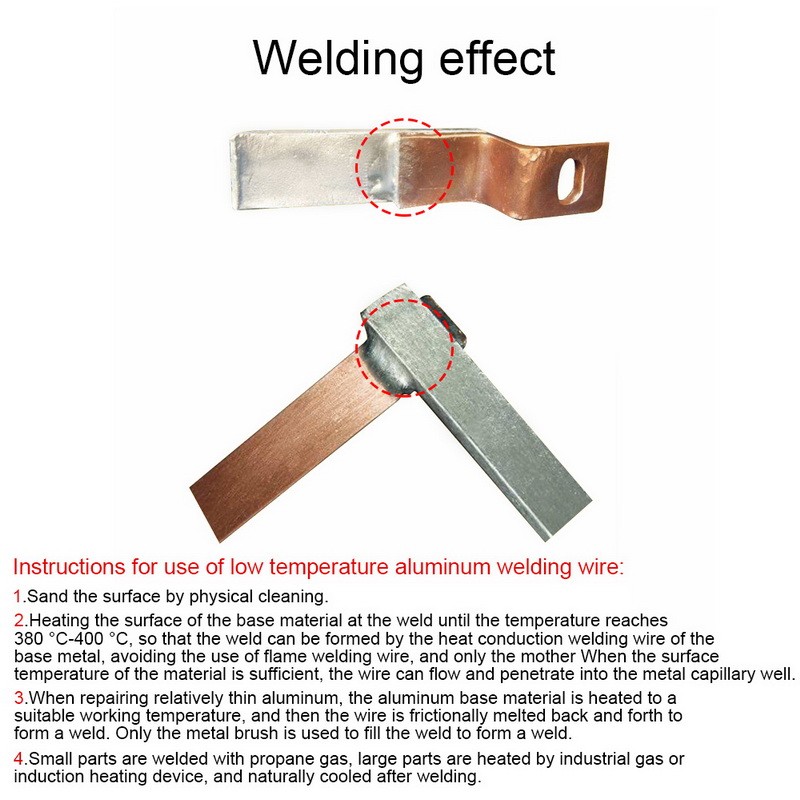

5. 완벽한 용접 효력 -- 품목이 내부 분말, 중대한 weldability 및 내식성, 높은 열 전도도, 높은 전기 전도도 및 우수한 가공 성과로 오기 때문에 가득 차있는 & 매끄러운 용접 효력으로 디자인해.

1. 널리 사용-용접 또는 표면 용접 합금 고강도, 좋은 forgeability & 좋은 내식성.

2. 좋은 품질 물자 -- 알루미늄 물자, nontoxic, 무취 및 튼튼한 물자로 만드는.

3. 필요로 한 땜납 분말 없음 -- 용접 핵심으로 알루미늄 합금으로 다른 유출 분말을 사용하고 소금 기초로 코팅하는 아무 필요도 없습니다.

4. 신청 -- 철사를 금속을 입히는 용접 충전물 철사와 살포 및 화염을 포함합니다. 그것은 또한 순수한 알루미늄을 위한 아르곤 아크 용접 그리고 채우는 물자를 위해 사용해, 전해질 알루미늄 식물의 알루미늄 버스 그리고 가이드 막대와 연결 및 전력, 화학, 음식 등.

5. 완벽한 용접 효력 -- 품목이 내부 분말, 중대한 weldability 및 내식성, 높은 열 전도도, 높은 전기 전도도 및 우수한 가공 성과로 오기 때문에 가득 차있는 & 매끄러운 용접 효력으로 디자인해.

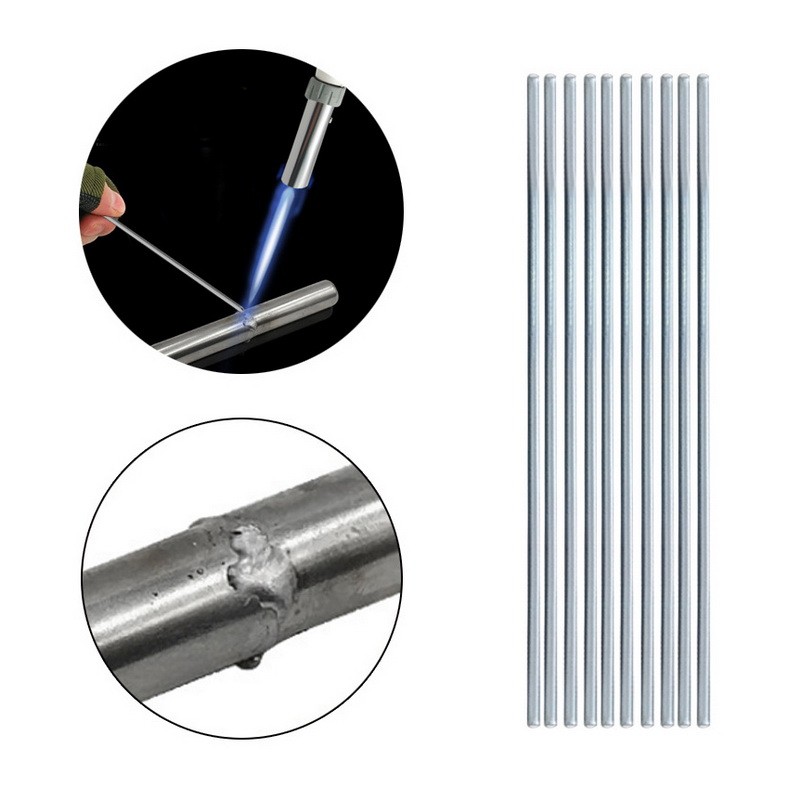

사용법:

1. 육체 표면을 청소하고 닦으십시오.

2. 와이어의 온도가 작동 온도 420 °까지 될 때까지 금속 재료의 표면을 가열하십시오.

3. 알루미늄 기초 금속은 얇은 알루미늄을 고칠 때 적당한 작동 온도에 가열되고, 그 후에 철사 마찰을 사용하고 용접을 형성하기 위하여.

4. 프로판 가스를 사용하여 작은 물체를 용접하고 산업 가스 또는 유도 가열 장치를 사용하여 큰 것을 가열하고 용접해야합니다.

주의:

1. 두꺼운 조각, 그것을 가열하는 것이 더 어렵습니다, 그래서 적당한 열원을 사용하는 것이 중요합니다.

2. 기본 금속의 표면 온도가 용접 와이어의 작동 온도에 도달하면 용접을 시작할 수 있습니다.

3. Oxyacetylene 용접을 사용할 때 중립 화염 용접을 사용해야하지만 직접 와이어를 태우지 마십시오.

4. 적용 가능한 열원: 프로판 oxyacetylene와 같은 등.

5. 저장: 건조하고 송풍된 장소에서 저장하십시오.

1. 육체 표면을 청소하고 닦으십시오.

2. 와이어의 온도가 작동 온도 420 °까지 될 때까지 금속 재료의 표면을 가열하십시오.

3. 알루미늄 기초 금속은 얇은 알루미늄을 고칠 때 적당한 작동 온도에 가열되고, 그 후에 철사 마찰을 사용하고 용접을 형성하기 위하여.

4. 프로판 가스를 사용하여 작은 물체를 용접하고 산업 가스 또는 유도 가열 장치를 사용하여 큰 것을 가열하고 용접해야합니다.

주의:

1. 두꺼운 조각, 그것을 가열하는 것이 더 어렵습니다, 그래서 적당한 열원을 사용하는 것이 중요합니다.

2. 기본 금속의 표면 온도가 용접 와이어의 작동 온도에 도달하면 용접을 시작할 수 있습니다.

3. Oxyacetylene 용접을 사용할 때 중립 화염 용접을 사용해야하지만 직접 와이어를 태우지 마십시오.

4. 적용 가능한 열원: 프로판 oxyacetylene와 같은 등.

5. 저장: 건조하고 송풍된 장소에서 저장하십시오.

참고:

1. 기본 금속의 표면은 깨끗해야합니다.

2. 기본 금속 온도 도달 420 도 포함하여 과정에서 용접 기본 금속 온도 유지되어야 420 ° 온도 수 높거나 낮은.

1. 기본 금속의 표면은 깨끗해야합니다.

2. 기본 금속 온도 도달 420 도 포함하여 과정에서 용접 기본 금속 온도 유지되어야 420 ° 온도 수 높거나 낮은.

---제품 사진---